Designing a metal enclosure may seem simple, but without experience in fabrication, it can quickly become complex. At Mettler Design, we understand that many engineers and innovators excel in their fields but may not have specialized training in sheet metal design. That’s why we’ve compiled this guide—to help you design smarter, avoid costly rework, and achieve professional-grade results.

1. Metal Selection: The Foundation of Every Great Design

The first step in any sheet metal design is choosing the right material. Each metal has unique strengths:

- Aluminum is lightweight, corrosion-resistant, and easy to machine—perfect for sleek enclosures.

- Cold Rolled Steel offers superior stiffness and cost efficiency for indoor applications.

- Stainless Steel provides exceptional corrosion resistance and a clean, modern look.

- Galvanneal Steel enhances durability in moist environments.

- Copper delivers unmatched electrical conductivity for specialized enclosures.

Selecting the correct metal type and thickness ensures performance, aesthetics, and longevity.

2. Bending Metal: Achieving the Right Radius

Metal bending defines both form and functionality. Using a press brake, sheet metal is shaped with a specific bend radius—the curvature inside the bend. Always consider:

- Functionality: Allow space for fasteners and cutouts.

- Aesthetics: Rounded bends add a sleek, professional finish.

To prevent distortion, keep cutouts at least one bend radius away from any edge.

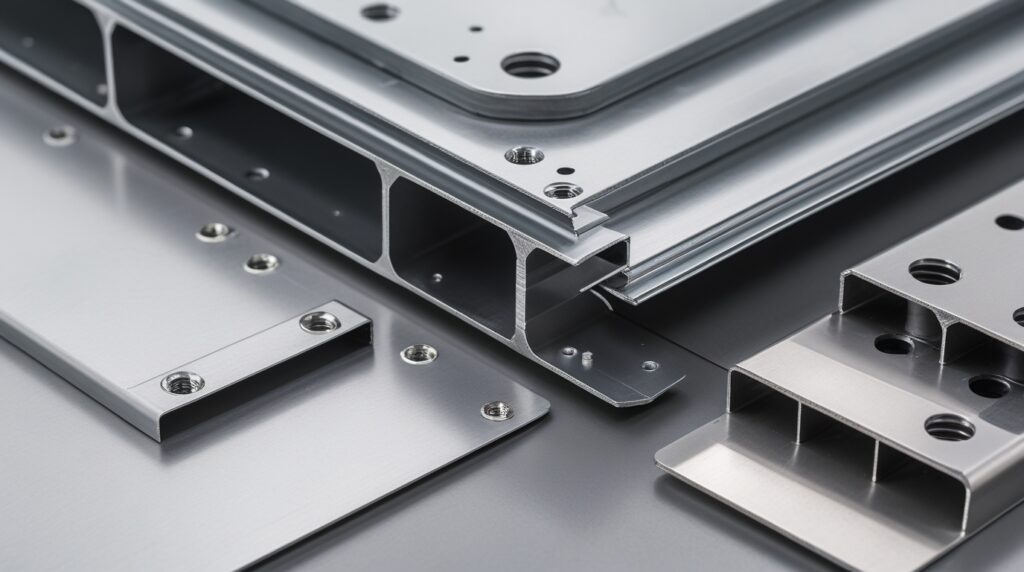

3. Self-Clinching Fasteners: Strength in Every Connection

For durable assembly, self-clinching fasteners (PEM® nuts, studs, and standoffs) are essential. They ensure a secure hold without compromising sheet integrity—ideal for mounting PCBs, connectors, or structural parts. At Mettler Design, we integrate these fasteners seamlessly to enhance functionality and reliability.

4. Welding: Seamless Precision and Strength

From spot to seam welding, the right technique determines your product’s durability and appearance. Our preferred method—Cold Metal Transfer (CMT) welding—delivers a clean, seamless finish with minimal heat distortion. This method is ideal for thin sheets and watertight, EMI-resistant designs.

5. Finishing: The Final Touch of Excellence

Finishing transforms raw metal into a professional masterpiece. Mettler Design offers:

- Powder Coating for durable, vibrant protection.

- Anodizing and Chem-Film Coating for corrosion resistance.

- Digital Printing & Silkscreening for custom branding and clear labeling.

- Bare Metal Finishes like brushed or tumbled textures for a refined industrial look.

Each finish not only enhances appearance but also improves functionality and longevity.

Build with Confidence at Mettler Design

At Mettler Design, we specialize in transforming concepts into precision-engineered metal enclosures. Whether you need custom cutouts, welding solutions, or premium finishes, our team ensures every detail aligns with your design intent.

Explore more insights and expert resources on Mettler Design’s website to bring your next metal fabrication project to life.