At Mettler Design, we were engaged by a client to engineer a reverse two-seater trike that would combine innovative product design, safety, and modularity with cost-efficient manufacturing potential. The objective was to create a versatile vehicle platform that could appeal to both investors and end-users, while leaving room for future electric mobility integration.

This project reflects our ability to deliver prototyping, testing, and design optimization for modern transportation solutions.

PROOF OF CONCEPT: INITIAL PRODUCT DESIGN

To begin, we developed a minimum viable product (MVP) as a proof of concept. This prototype enabled the client to showcase the vehicle to potential investors while allowing us to evaluate its dynamics, suspension, and ergonomics at a lower cost.

The trike was designed using readily available aftermarket components, minimizing custom part development and keeping production costs under control. An air-cooled engine paired with an automatic transmission powered the vehicle, while a belt drive system at the rear simplified maintenance. Furthermore, the chassis was engineered to remain configurable for a future EV variant, ensuring long-term flexibility.

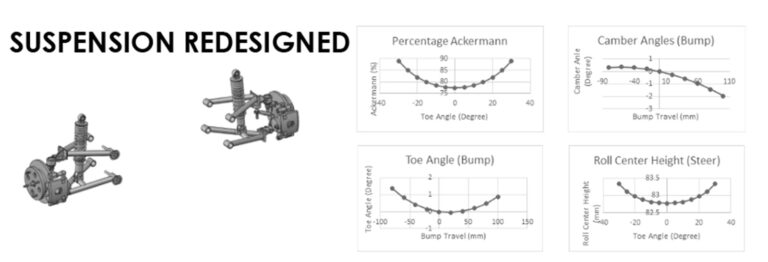

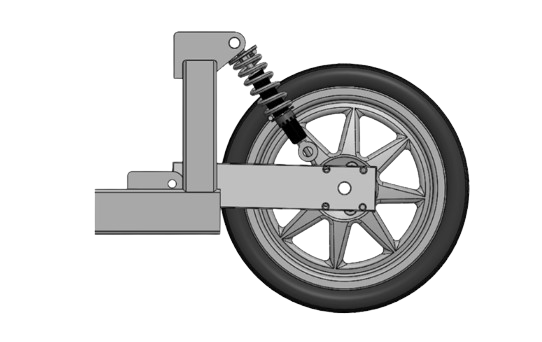

To improve usability, we designed an independent suspension system tuned for comfort, providing a smooth ride on diverse terrains. The inclusion of bucket seats with ample legroom and a car-like driving interface gave riders familiarity and confidence.

TESTING

DESIGN REFINEMENTS BASED ON TESTING RESULTS

Following extensive testing, we introduced a number of refinements to improve safety, stability, and comfort. The suspension system was further optimized for better handling, traction, and durability, ensuring reliable performance during sharp turns and load shifts.

Additionally, ergonomic upgrades were made to the seating and driving interface, enhancing overall comfort for long rides. Based on user feedback polls, we also added a roof structure to improve weather protection and reduce occupant exposure, thereby increasing the trike’s value proposition.

For manufacturing feasibility, we developed multiple body design concepts, analyzing each option against production estimates and cost targets. Ultimately, a simplified body design was chosen to reduce upfront investment, enabling the client to move quickly into small-scale production.

A roof was added to the final design to make sure the product offers more value for money and reduce the exposure of the occupants. This decision was based off multiple feedback polls where target audience demanded reduced exposure and better weather shielding.

The final design successfully integrated product design innovation, prototyping validation, and manufacturing efficiency into one cohesive solution. The result is a practical, cost-effective three-wheeler that balances performance, comfort, and market viability.