Innovation in today’s fast-paced market requires quick idea validation and faster product development cycles. This is where rapid prototyping comes in—a method that allows businesses and engineers to design, test, and refine products quickly, reducing time-to-market while minimizing risks.

What is Rapid Prototyping?

Rapid prototyping is the process of quickly creating a scaled-down version or working model of a product to test its design, functionality, and usability. Unlike traditional prototyping, which may take weeks or months, rapid prototyping leverages advanced tools like 3D printing, CAD (Computer-Aided Design), and CNC machining to speed up the process.

It enables teams to spot flaws early, gather user feedback, and make necessary improvements before moving into full-scale production.

Key Benefits of Rapid Prototyping

Rapid prototyping has transformed industries ranging from automotive to healthcare. Its major benefits include:

- Faster development cycles – Products reach the market quicker.

- Cost efficiency – Detect design flaws before mass production.

- Improved collaboration – Visual models help teams and stakeholders communicate ideas better.

- Flexibility – Designs can be modified and iterated quickly.

- Risk reduction – Early testing reduces the chance of product failure.

Types of Rapid Prototyping

There are several techniques under rapid prototyping, each suited to different applications.

1. 3D Printing (Additive Manufacturing)

- Creates prototypes layer by layer using materials like plastic, resin, or metal.

- Ideal for complex designs and small-scale testing.

- Widely used in industries like aerospace, healthcare (prosthetics), and consumer products.

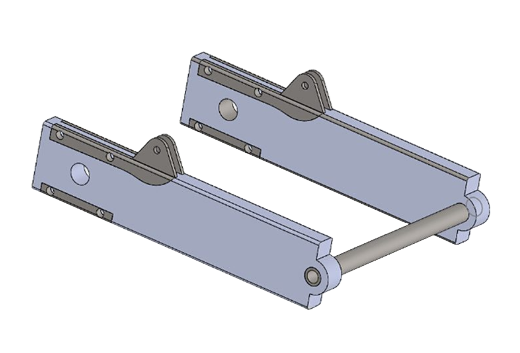

2. CNC Machining

- A subtractive process that carves out prototypes from solid blocks of material.

- Produces strong, precise prototypes that mimic the final product.

- Common in automotive and industrial applications.

3. Stereolithography (SLA)

- Uses UV lasers to solidify liquid resin into solid layers.

- Produces smooth and detailed prototypes.

- Suitable for industries requiring high accuracy, like dental and medical fields.

4. Selective Laser Sintering (SLS)

- Uses a laser to fuse powdered material (plastic or metal).

- Produces durable and functional prototypes.

- Great for testing mechanical properties.

Applications of Rapid Prototyping

Rapid prototyping is no longer limited to R&D labs. Today, it plays a crucial role in multiple industries:

Product Design and Development

- Quickly test multiple design variations.

- Identify ergonomic or usability issues early.

Healthcare and Medical Devices

- Create patient-specific implants, prosthetics, and surgical models.

- Reduce development costs for medical tools.

Automotive and Aerospace

- Develop lightweight components for testing.

- Improve fuel efficiency and performance through iterative design.

Education and Research

- Helps students and researchers bring concepts to life.

- Encourages hands-on learning and innovation.

Best Practices for Effective Rapid Prototyping

To maximize the potential of rapid prototyping, businesses should follow a structured approach:

- Define clear goals – Know what you’re testing (function, form, or usability).

- Select the right technology – Match the method to the material and purpose.

- Encourage collaboration – Involve engineers, designers, and stakeholders early.

- Iterate frequently – Use rapid feedback cycles to refine designs.

- Balance cost vs. accuracy – Not all prototypes need high precision; match fidelity to purpose.

Conclusion

Rapid prototyping has become a game-changer in modern product development. By enabling faster iterations, cost savings, and better collaboration, it helps businesses stay ahead of the competition. Whether you’re designing the next breakthrough medical device, an innovative consumer gadget, or an advanced aerospace component, rapid prototyping offers the agility needed to bring ideas to life—faster and smarter.