Fixture design often operates behind the scenes, yet it plays a decisive role in the success of modern manufacturing. While product design and automation frequently take center stage, fixture design quietly ensures accuracy, repeatability, and efficiency across every production run. As industries push for tighter tolerances, faster cycles, and higher quality, fixture design has become more critical than ever.

At Mettler Design, fixture design is not treated as an afterthought. Instead, it is approached as a strategic engineering discipline that directly impacts productivity, safety, and cost control. By combining advanced CAD tools, real-world manufacturing expertise, and a deep understanding of industry requirements, Mettler Design helps organizations transform complex manufacturing challenges into streamlined, repeatable processes.

In this blog, we explore fixture design in modern engineering, its importance across industries, emerging technologies, and future trends shaping this essential field.

Understanding Fixture Design in Modern Engineering

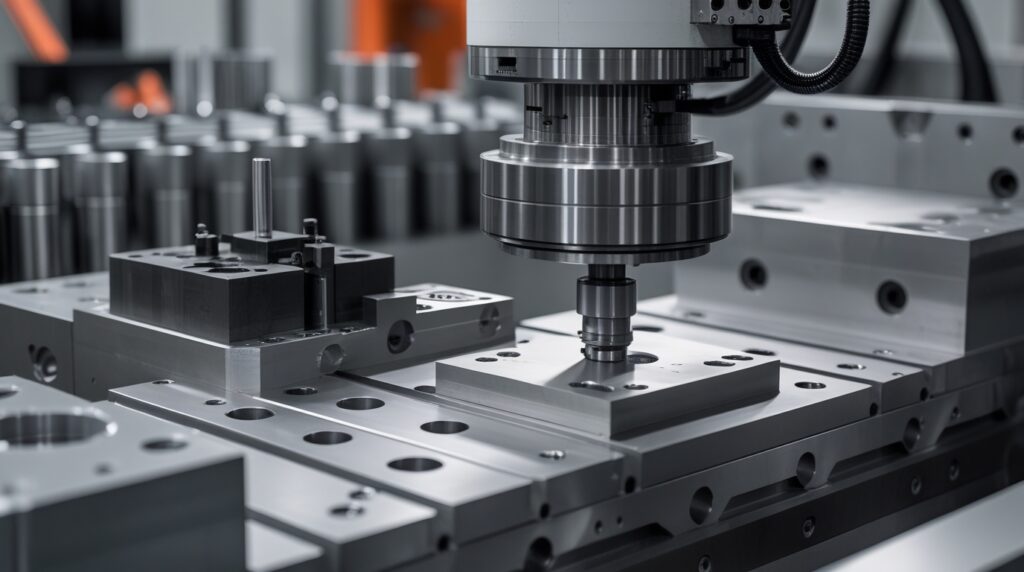

Fixture design refers to the creation of specialized tools or devices that securely hold, locate, and support a workpiece during manufacturing operations. These operations may include machining, assembly, welding, inspection, or testing. Unlike generic holding tools, fixtures are purpose-built to ensure consistent positioning and stability throughout production.

Key Functions of Fixture Design

A well-engineered fixture delivers several critical functions:

- Accurate positioning of the workpiece

- Repeatability across high-volume production

- Stability under machining or assembly forces

- Operator safety and ergonomics

- Compatibility with automation systems

Because of these requirements, fixture design blends mechanical engineering principles with practical manufacturing knowledge. At Mettler Design, engineers focus on creating fixtures that not only meet technical requirements but also integrate seamlessly into existing workflows.

The Importance of Fixture Design in Manufacturing

Precision and Dimensional Accuracy

Precision remains the foundation of manufacturing excellence. Fixture design directly influences dimensional accuracy by eliminating movement, vibration, and misalignment during operations. When fixtures hold components securely, manufacturers achieve tighter tolerances and consistent quality.

Moreover, precision fixtures reduce the risk of part distortion, especially when working with delicate or high-value materials. As a result, organizations experience fewer defects and improved product reliability.

Improved Efficiency and Productivity

Fixture design also drives efficiency. Well-designed fixtures reduce setup time, simplify part loading, and enable faster cycle times. Consequently, manufacturers can produce more parts in less time without sacrificing quality.

Additionally, optimized fixtures support automation by allowing robotic systems and CNC machines to operate smoothly. This seamless integration becomes especially valuable for high-volume or complex production environments.

Enhanced Workplace Safety

Safety plays a crucial role in modern manufacturing. Fixture design minimizes manual handling by securely holding workpieces in place. As a result, operators face fewer ergonomic risks and reduced exposure to hazardous conditions.

At the same time, ergonomic fixture design improves operator comfort, which in turn boosts productivity and reduces fatigue-related errors.

Cost Reduction and Waste Minimization

Effective fixture design significantly reduces production costs. By minimizing errors, scrap rates, and rework, fixtures help manufacturers control expenses while improving yield. In addition, optimized fixtures reduce material waste and energy consumption, aligning with sustainable manufacturing goals.

Mettler Design emphasizes cost-efficient fixture solutions that deliver long-term value rather than short-term fixes.

Fixture Design in Modern Industries

Fixture Design in the Automotive Industry

The automotive sector relies heavily on precision and repeatability. Fixture design supports the assembly of engine blocks, transmissions, chassis components, and body panels. Because even minor deviations can affect vehicle performance and safety, fixture accuracy becomes essential.

Furthermore, automotive production lines demand high throughput. Modular and automated fixture systems enable rapid changeovers while maintaining consistent quality across large volumes.

Fixture Design in Aerospace Manufacturing

Aerospace manufacturing demands exceptional accuracy and reliability. Components must meet strict regulatory and safety standards, often with complex geometries and advanced materials.

Fixture design in aerospace supports machining, inspection, and assembly processes while ensuring structural integrity. Mettler Design applies advanced analysis and simulation techniques to develop aerospace fixtures that meet exacting requirements.

Fixture Design in Electronics Manufacturing

Electronics manufacturing presents unique challenges due to delicate components and tight spaces. Fixtures must prevent damage while ensuring precise alignment for PCB assembly and testing.

By incorporating electrostatic discharge (ESD) considerations and precision locating features, fixture design ensures electrical connectivity and product reliability throughout production.

Fixture Design in Medical Device Manufacturing

The medical device industry requires unparalleled precision, cleanliness, and compliance. Fixture design supports the manufacturing of implants, surgical tools, and diagnostic equipment while meeting strict regulatory standards.

At Mettler Design, fixture solutions for medical applications focus on repeatability, sterility, and traceability, ensuring consistent quality and patient safety.

Technological Advancements Transforming Fixture Design

Computer-Aided Design (CAD)

CAD software has revolutionized fixture design by enabling detailed modeling, rapid iteration, and seamless collaboration. Engineers can visualize fixture-part interactions early in the design process, reducing errors and development time.

Mettler Design leverages advanced CAD tools to create robust, production-ready fixture designs that integrate effortlessly with manufacturing systems.

Finite Element Analysis (FEA)

FEA allows engineers to simulate real-world forces and stresses acting on fixtures. By predicting deformation and failure points, designers can optimize fixture strength and rigidity before fabrication.

As a result, manufacturers benefit from durable fixtures that maintain accuracy under demanding conditions.

Rapid Prototyping and Validation

Rapid prototyping accelerates fixture development by enabling quick fabrication of prototypes. Engineers can test fit, function, and ergonomics early, making refinements before final production.

This approach reduces development risk while shortening time-to-market.

Modular Fixture Systems

Modular fixtures provide flexibility and scalability. Instead of designing a fixture from scratch for every application, engineers can reconfigure modular components to suit different parts or processes.

This adaptability proves especially valuable in low-volume or high-mix production environments.

The Future of Fixture Design in Modern Engineering

Digital Twins for Fixture Optimization

Digital twin technology enables engineers to create virtual replicas of fixtures and simulate their performance under real operating conditions. These simulations support optimization before physical production, saving time and cost.

Digital twins also help identify potential issues early, improving reliability and performance.

Additive Manufacturing and 3D Printing

Additive manufacturing is transforming fixture design by enabling complex geometries and lightweight structures that traditional methods cannot achieve. 3D-printed fixtures reduce lead times while offering customization and cost efficiency.

Mettler Design continues to explore additive manufacturing to deliver innovative fixture solutions tailored to unique production needs.

Smart Fixtures and Industry 4.0

Smart fixtures integrate sensors, data analytics, and connectivity to provide real-time feedback. These fixtures monitor forces, alignment, and wear, enabling predictive maintenance and process optimization.

As Industry 4.0 adoption grows, smart fixture design will play a pivotal role in data-driven manufacturing environments.

Why Choose Mettler Design for Fixture Design Solutions?

Mettler Design combines engineering expertise with practical manufacturing insight to deliver high-performance fixture design solutions. By focusing on precision, efficiency, and scalability, the team ensures each fixture supports long-term production success.

Key advantages include:

- Industry-specific fixture expertise

- Advanced CAD and simulation capabilities

- Emphasis on manufacturability and cost efficiency

- Collaborative design approach tailored to client needs

Whether supporting automotive, aerospace, electronics, or medical manufacturing, Mettler Design delivers fixture solutions that enhance quality and productivity.

Conclusion: Fixture Design as a Strategic Advantage

Fixture design in modern engineering is far more than a supporting function—it is a strategic advantage. By ensuring precision, efficiency, safety, and cost control, fixture design directly impacts manufacturing performance and product quality.

As technologies such as digital twins, additive manufacturing, and smart systems continue to evolve, fixture design will remain at the core of advanced manufacturing strategies. With its commitment to innovation and engineering excellence, Mettler Design stands ready to help organizations unlock the full potential of fixture design.

If your manufacturing processes demand higher accuracy, faster production, and reliable results, investing in expert fixture design is not optional—it is essential.