In today’s fast-paced industrial landscape, achieving accuracy, safety, and cost-efficiency is paramount for any manufacturing process, especially when creating intricate industrial parts.

The days of manual machining, with its inherent risks of human error, operator accidents, product inconsistencies, and time-consuming nature, are largely in the past. Today’s industrial needs have shifted the focus to automation.

This is where CNC cutting machines come in, completely changing the narrative. CNC, which stands for Computer Numerical Control, has become the go-to manufacturing process for countless industries.

These machines use pre-programmed computer software to operate a wide range of factory tools and machinery, transforming raw materials like aluminum, wood, plastics, and various hard metals into precise components.

A typical CNC cutting machine consists of three core components: a command function, a drive system, and a feedback system. Essentially, it is a computer-driven tool that expertly cuts solid raw material into complex shapes.

This is all made possible by digital instructions generated using Computer-Aided Manufacturing (CAM) or Computer-Aided Design (CAD) software.

These programs are capable of writing G-code, a set of numerical values that the CNC machine’s controller interprets and executes from start to finish. The controller’s computer reads the design, then moves the cutting tool or workpiece along multiple axes to cut the desired shapes into the raw material.

Unlike manual cutting, which requires constant human intervention, automatic cutting machines read specific machining commands, ensuring a precise and efficient cutting solution.

Exploring the Different Types of CNC Cutting Machines

CNC Milling Machines

CNC milling machines are undeniably the most widely used CNC machines for a vast array of industrial applications. These versatile machines have integrated tools primarily used for cutting and drilling. The mills develop and convert specialized programs, or G-code, to guide the spindle’s movement in various directions. All you have to do is place the workpiece in the machine, and the computer takes over.

The computer code meticulously instructs and guides the tool and spindle movement, ensuring every cut is accurate, transforming the workpiece into a precisely planned custom item. CNC milling machines are used for tapping, face milling, shoulder milling, turning, and drilling.

They can have a configuration of three to six axes, with the simplest 3-axis CNC machines controlling movements along the X-axis (horizontal), Y-axis (horizontal), and Z-axis (depth). These machines are generally larger and more expensive than other cutting machines because they are designed to cut very hard metals, whereas CNC routers, for instance, are better suited for softer materials like wood, plastic, and soft metals.

CNC Lathe Machines

Conversely, CNC lathe machines are shorter and more compact, with fewer axes. Their main strength lies in their ability to rotate materials while in use. The lathe is controlled programmatically by the computer, allowing it to manipulate and transmit the material with remarkable speed and precision. Even a semi-skilled worker can operate them after the initial setup, making them ideal for the mass production of items like capstan and turret parts. The only downside is their lack of an automated feeding mechanism.

CNC Drilling Machines

CNC drilling equipment utilizes a spinning cutting tool to create holes in a stationary object, much like a traditional drill. However, thanks to CNC technology, they offer greater precision and adaptability. The holes they create have incredibly tight tolerances of up to 0.001mm. These machines often feature tool turrets that can hold several drill bits, allowing for rapid switching during production. They work exceptionally well with materials such as wood, plastic, and metal and are commonly used to manufacture machined shafts, gear blanks, and hubs.

CNC Laser Cutting Machines

Similar to plasma cutters, CNC laser cutting machines can slice through robust materials. However, instead of using ionized gas, they employ a powerful, highly focused laser. A key advantage of laser cutters is their superior precision and surface quality.

This is because a laser’s point of contact is smaller and less diffuse than a plasma torch. Although they offer similar accuracy and cutting depth, laser cutters are more expensive than plasma cutters.

The laser power can be adjusted to easily cut through materials of varying thickness and toughness. These machines are particularly effective for cutting sheet materials. The laser beam moves back and forth, melting or vaporizing the material to achieve a precise cut.

Another significant benefit is the ability to generate a wide range of complex patterns. The cuts and edges are so exact and clean that post-production polishing is often unnecessary. Therefore, CNC laser cutting is the perfect choice for projects requiring tight tolerances and a precise output.

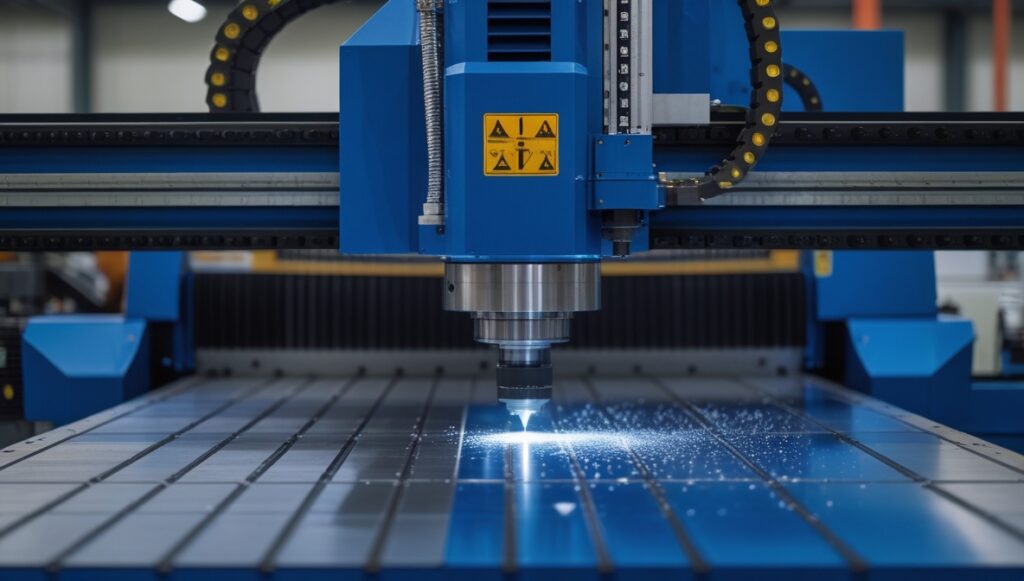

CNC Waterjet Cutting Machines

CNC waterjet cutters utilize extremely high-pressure water jets to cut through materials. They are a great choice for temperature-sensitive materials like certain plastics and aluminum, which might otherwise melt at high temperatures. For more effective cutting, you can even add abrasives like garnet or aluminum oxide to the water stream.

While a CNC waterjet cutter with comparable specifications is more expensive than a CNC plasma cutter, it’s generally less costly than a laser cutter. However, a major drawback is that they are notably slower than both laser and plasma cutters.

CNC Plasma Cutting Machines

CNC plasma cutting machines achieve high-level precision and are compatible with a wide variety of materials, much like their laser counterparts. However, they use a high-powered plasma flame instead of a laser.

The plasma torch generates a powerful stream of charged gas that can reach temperatures up to 50,000°F. This immense heat effectively slices through electrically conductive materials.

NC Electrical Discharge Machines

Also known as EDM or “sparks,” NC Electrical Discharge Machines are a unique type of CNC machine that manipulates materials into the required shape using controlled electric sparks. The material is positioned between electrodes at the top and bottom. A computer-controlled electrical discharge then erodes the material to form the desired shape.

CNC Router Machines

CNC router machines are similar to CNC mills but are primarily used for softer materials and are generally less accurate. They use computer numerical control to guide the router spindle and tool paths, shaping materials like wood, steel, composites, aluminum, foam, and plastic. Composed of a mechanical base, stepper motors, drivers, a spindle, and a power supply, these machines decrease waste, improve accuracy, and speed up production. They are proficient at creating both modest projects and complex prototypes in three dimensions. Like CNC mills, they also have a variety of axes, ranging from three to six.

CNC 3D Printers

Finally, 3D printers are also a form of CNC machine that builds elements one layer at a time. Using CAD and CAM processes to create the design, the 3D printer then translates that design into a three-dimensional object, from small components to entire houses and structures.

Conclusion on the Types of CNC Cutting Machines

For quick, precise, and complex cuts, CNC cutting machines are indispensable. These computer-driven machines can transform raw materials into a finished product with consistent quality, superior accuracy, increased production speed, and enhanced operator safety. The right choice of CNC cutting machine ultimately depends on your specific needs and the materials you plan to work with.

If you are looking for professional CNC services to bring your designs to life, Mettler Design offers expert solutions. Contact us today to discuss your project!