CNC machining, mold making, and production support, from a team that speaks both engineering and manufacturing. Learn more

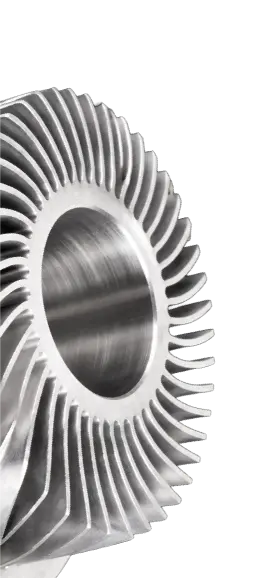

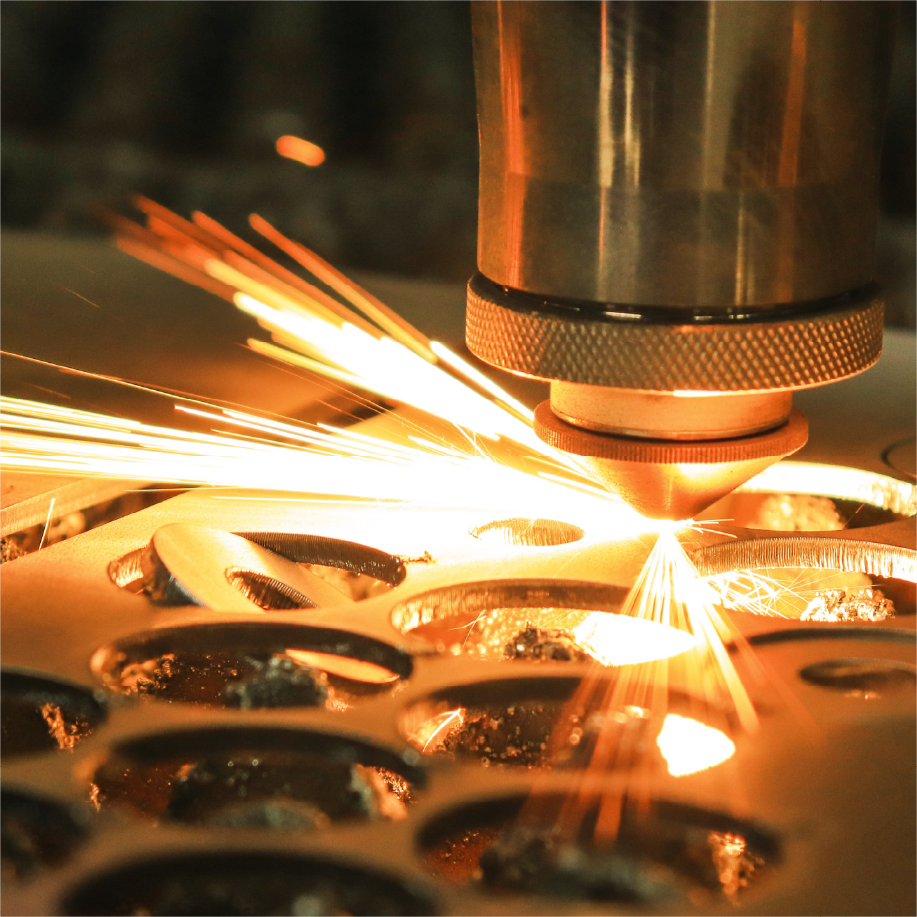

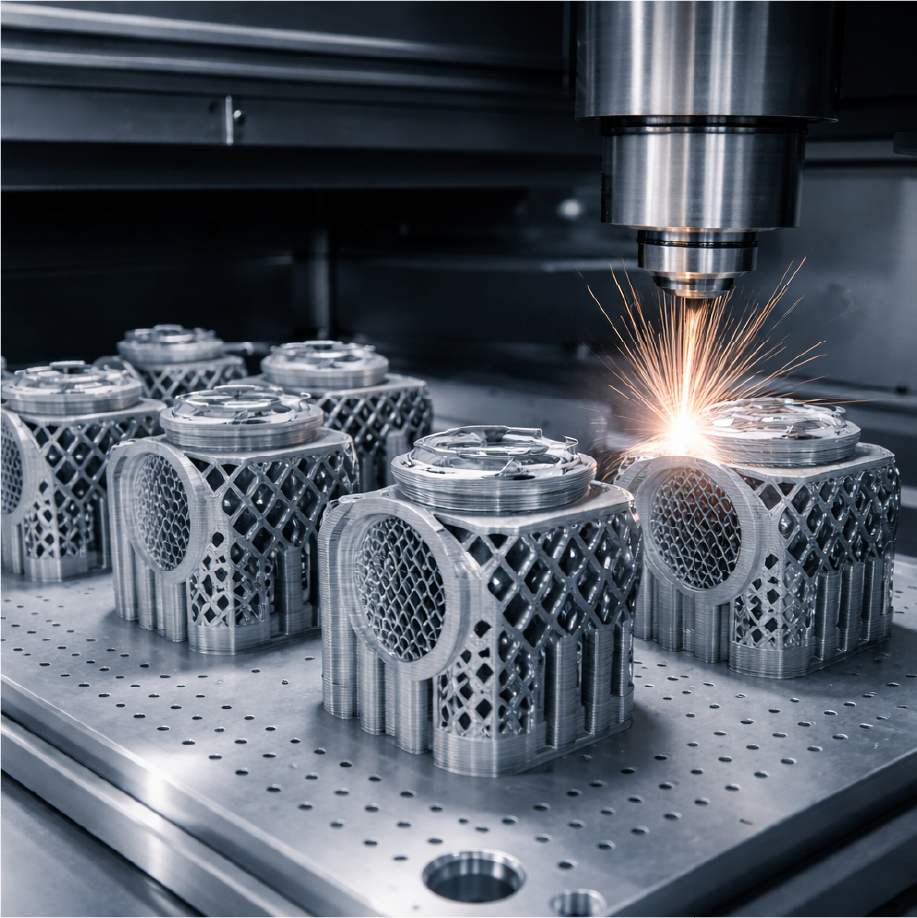

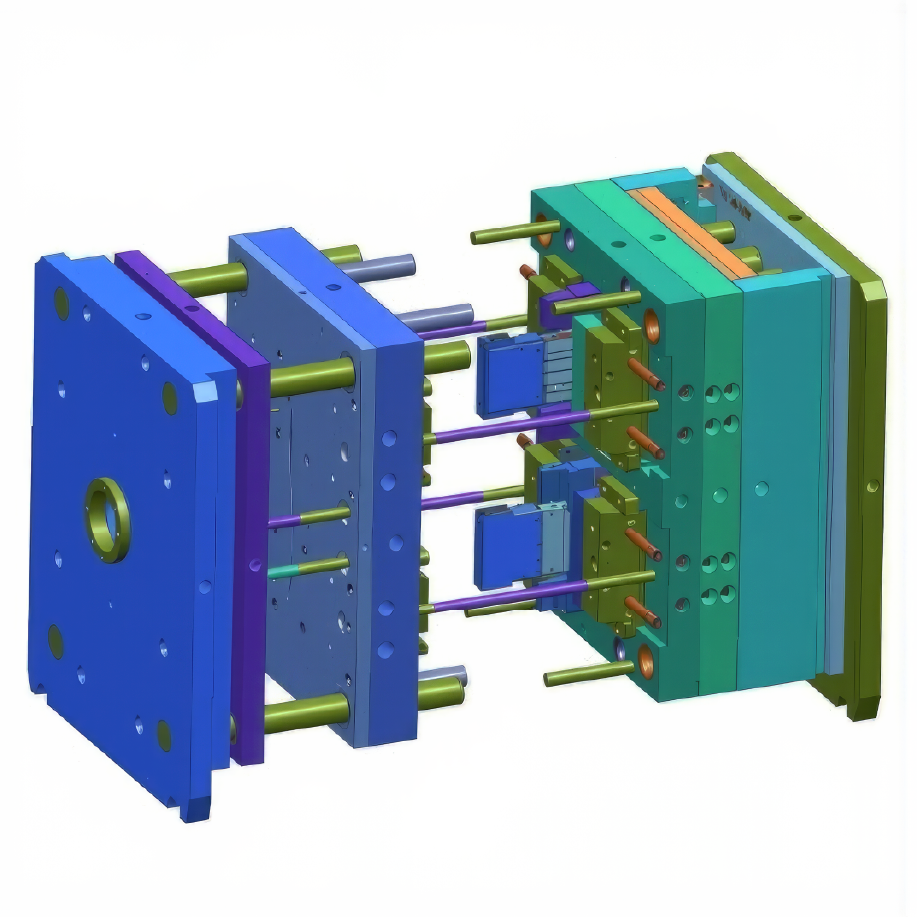

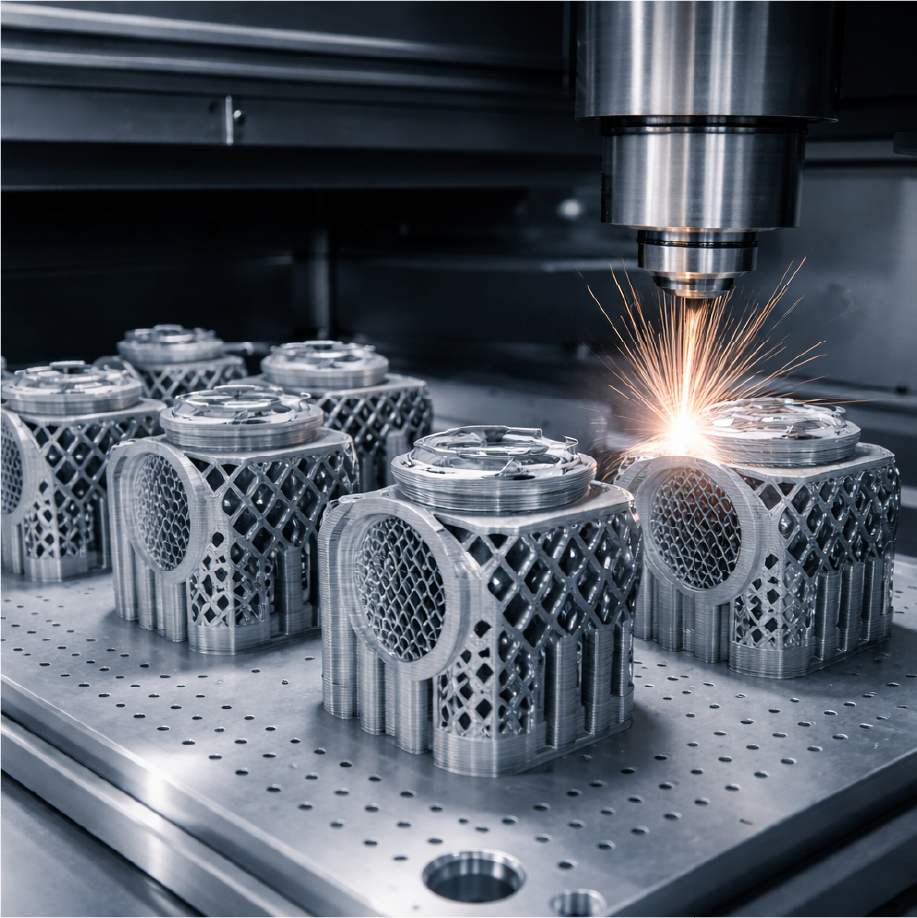

We build fast, accurate prototypes to help you validate design, fit, and function early. Using a mix of CNC machining, additive manufacturing, and tooling processes, we turn concepts into physical parts you can test, review, and refine.

From one-off prototypes to pre-production samples, we support functional testing and iteration, so issues are resolved early, timelines stay tight, and production decisions are made with confidence.

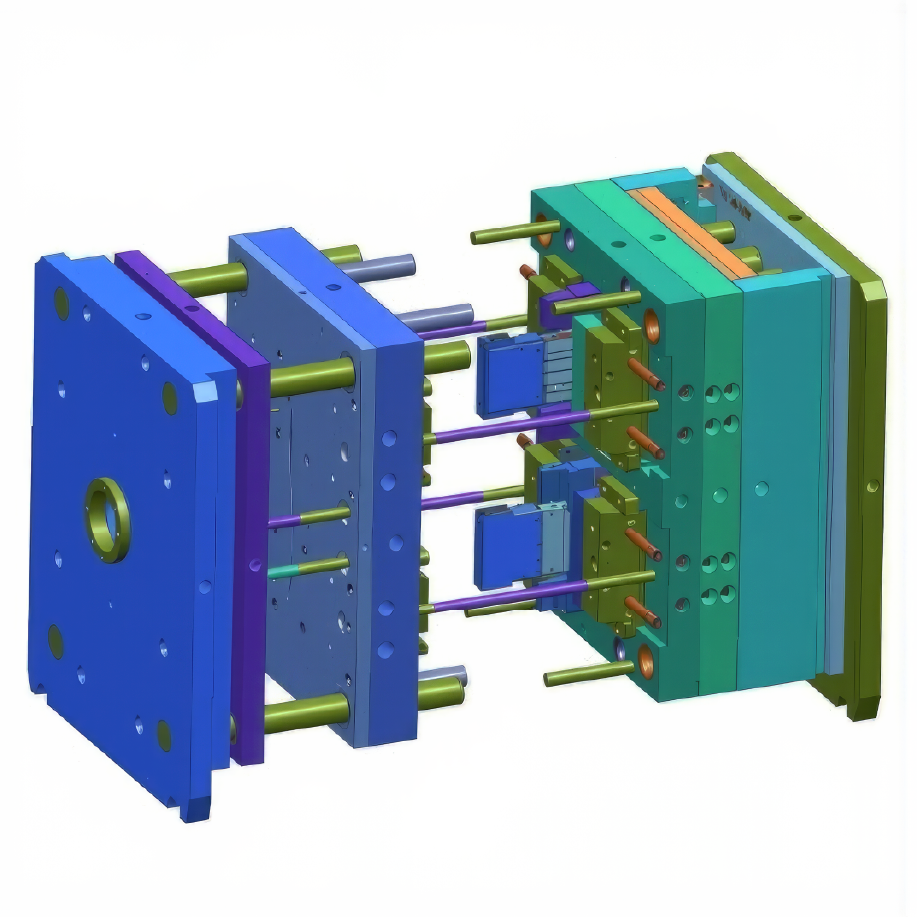

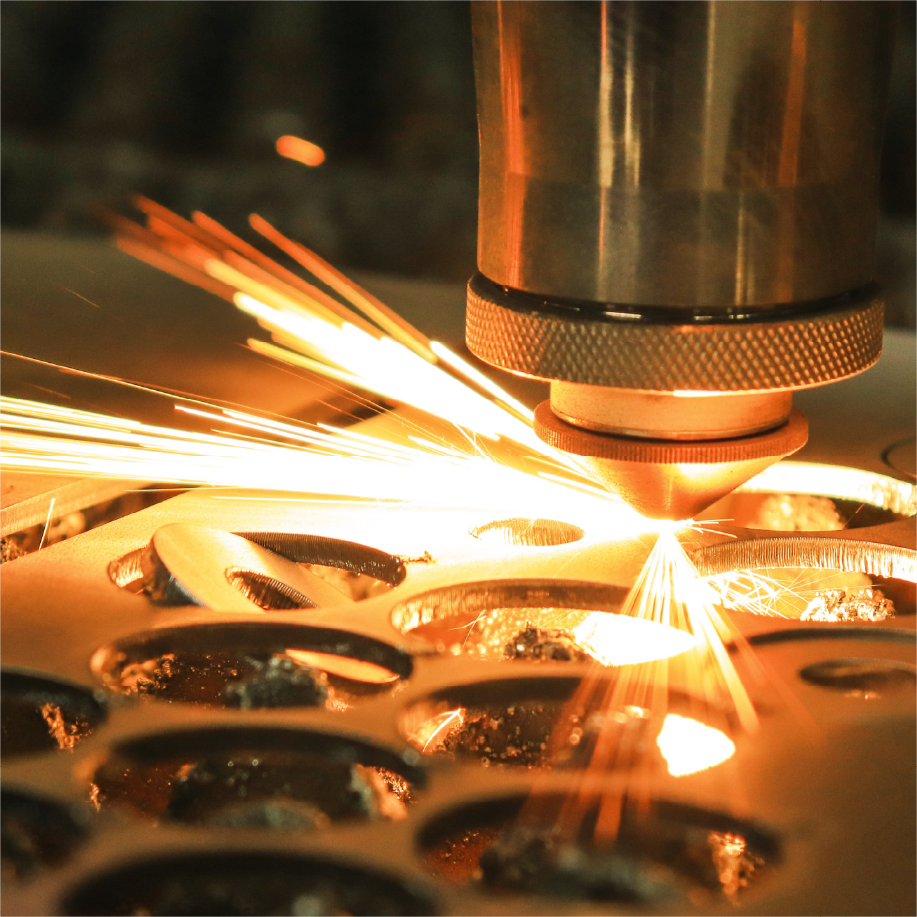

Our manufacturing facilities are equipped with high-precision CNC machining centers, EDM and wire-cut machines, grinders, measuring equipment, and injection molding presses.

This mix of equipment lets us handle everything from one-off prototypes to production tooling and repeat orders—while keeping quality and lead times under control.

Whether you need a single prototype, a production mold, or a long-term CNC partner, Mettler Design Inc. can support you from first sketch to finished part.

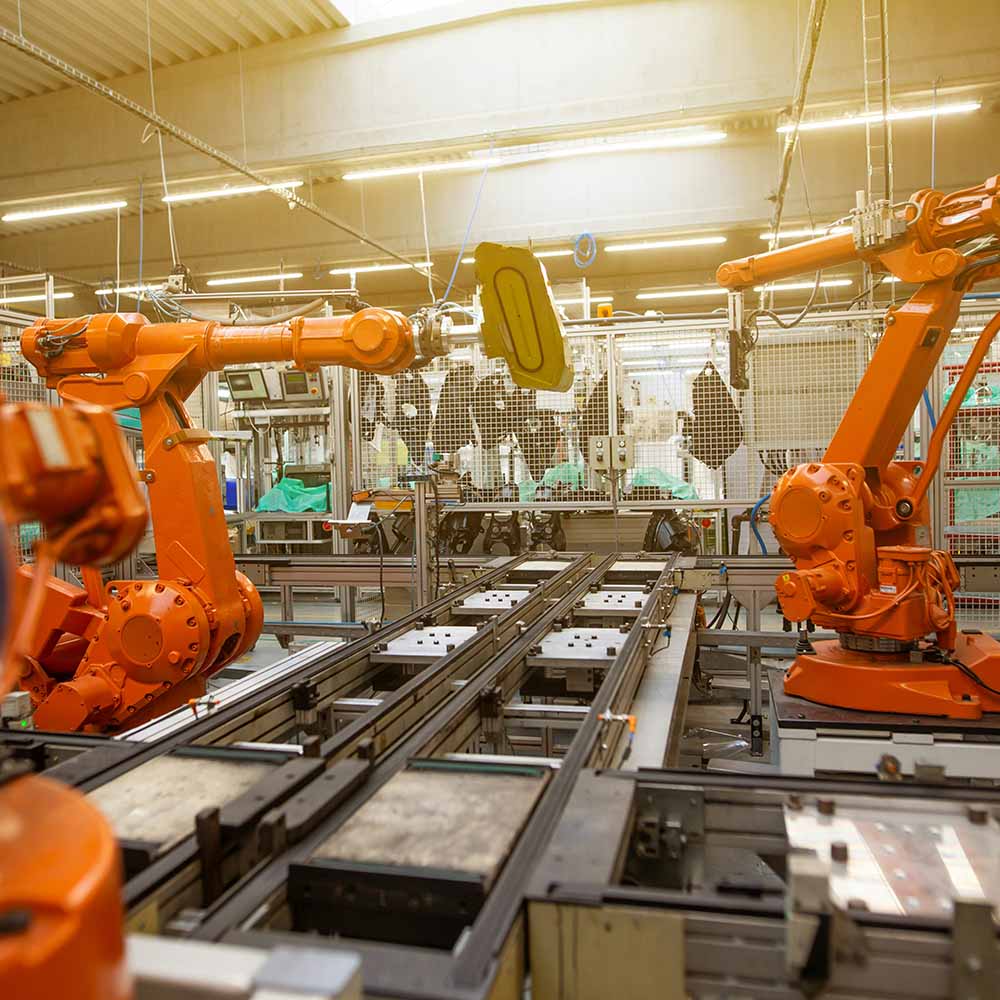

Mettler Design Inc. is an engineering-led manufacturing partner. We bridge the gap between design and production, helping you move from idea, to tooling, to finished parts without the usual friction.

Our team combines product designers, mechanical engineers, and manufacturing experts who work side by side with CNC and molding shops. That means you get parts that not only look right in CAD, but work right on the factory floor.

We support projects for automotive, electronics, industrial equipment, and consumer products, treating every job, small or large, with the same focus on accuracy, repeatability, and clear communication.

Stay ahead with our exclusive updates. No spam, just innovation.

Why Join?