Finite Element Analysis (FEA) is one of the most powerful tools engineers use to predict how a product or structure behaves under real-world conditions. Instead of relying solely on costly and time-consuming physical prototypes, FEA allows engineers to simulate conditions such as extreme heat, pressure, vibration, and seismic activity. By doing so, designers can spot vulnerabilities early, optimize their work, and deliver safer, stronger, and more efficient products.

What is Finite Element Analysis (FEA)?

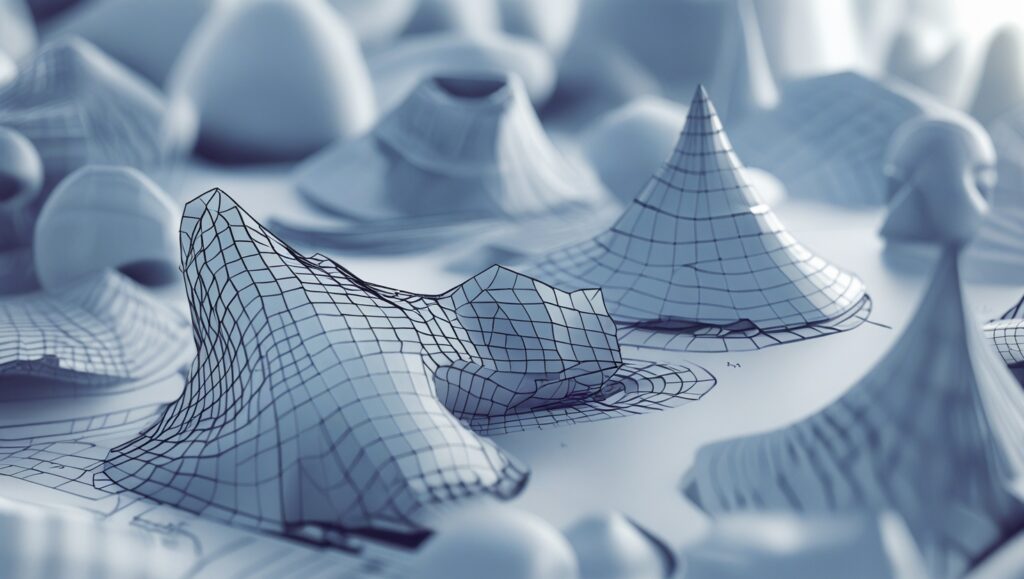

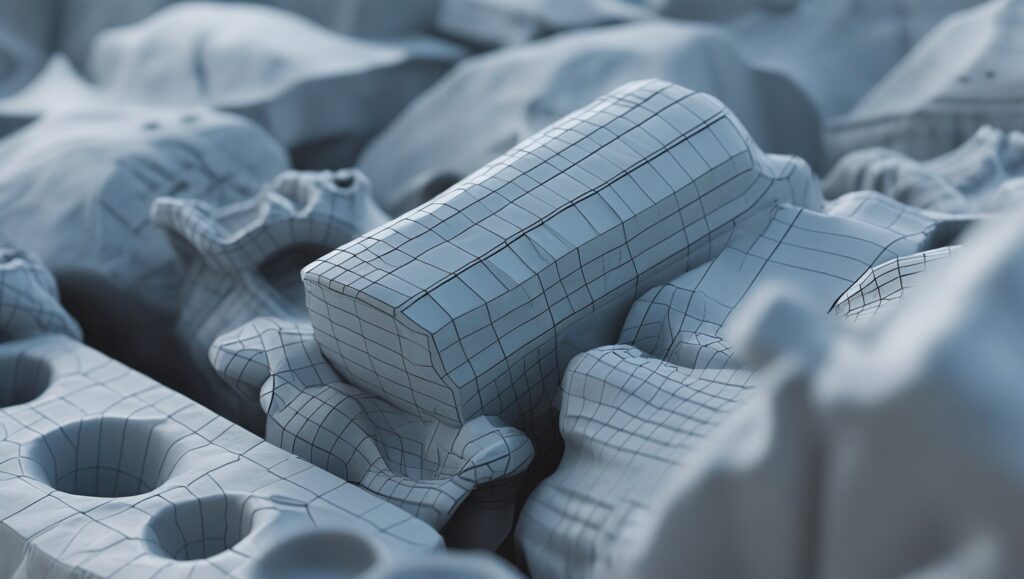

Finite Element Analysis (FEA) is a computer-based simulation method that breaks an object into smaller, simpler components called elements. These elements connect at points called nodes, forming a mesh. Mathematical equations, specifically partial differential equations (PDEs), are then applied to predict how the object responds to stress, strain, temperature, vibration, and other forces.

While FEA provides approximate solutions, it significantly reduces the need for building multiple prototypes. Engineers can test design concepts virtually, saving time and resources while improving product reliability.

How Finite Element Analysis (FEA) Works

The FEA process involves breaking a complex structure into thousands or even millions of elements. Each element is usually a geometric shape, such as a square or triangle, and together they form the mesh.

The simulation process includes three main steps:

1. Preprocessing

At this stage, engineers set up the analysis. They:

- Select element types.

- Define material properties.

- Apply loads and boundary conditions.

- Choose the type of analysis, such as modal analysis or static structural analysis.

2. Processing

Once the setup is complete, the software calculates the results by solving PDEs on each element. The outputs are then combined to provide a complete picture of the object’s behavior.

3. Postprocessing

Finally, engineers interpret the results. They review stress, strain, displacement, temperature variations, time history, and natural frequencies to make data-driven design decisions.

Accurate boundary conditions are critical at every step to ensure reliable predictions.

Governing Equations in Finite Element Analysis (FEA)

FEA relies on three governing equations to predict behavior:

- Equilibrium equations – Ensure opposing forces are balanced.

- Strain-displacement relations – Measure deformations caused by external impacts.

- Constitutive equations – Define material responses to forces, such as how steel or concrete behaves under stress.

Together, these equations form the mathematical foundation of FEA simulations.

Types of Finite Element Analysis (FEA) Tests

Different industries rely on various FEA tests to evaluate designs. Some of the most common include:

- Structural static analysis – Tests how a structure handles static loads and stresses.

- Thermal analysis – Evaluates the effects of temperature changes on materials.

- Modal analysis – Determines how vibrations affect structural integrity.

- Seismic calculations – Assesses how structures withstand ground movement and vibrations.

Common Use Cases of Finite Element Analysis (FEA)

FEA has wide applications across aerospace, automotive, civil engineering, and even biomechanics. Some key use cases include:

- Certifying crane load capacities.

- Building airport bridges.

- Determining brake or rotor lifespans.

- Improving machinery performance.

- Establishing servicing schedules.

- Ensuring compliance with legal and contractual standards.

In every case, FEA provides insights into safety, performance, and durability before physical testing begins.

Advantages of Finite Element Analysis (FEA)

Using Finite Element Analysis (FEA) offers several advantages, such as:

- Improved design quality – Engineers can observe how stresses transfer between connected elements.

- Faster testing – Virtual prototyping reduces design cycles from weeks to hours.

- Higher productivity – Teams create better products while using fewer materials.

- Enhanced insights – Both interior and exterior structures can be analyzed simultaneously.

- Multiple tests with one model – A single model can be reused for different conditions.

- Cost savings – Reduces prototype and manufacturing costs significantly.

Moreover, designers can quickly compare alternative designs and optimize the best one, leading to innovation without delays.

Disadvantages of Finite Element Analysis (FEA)

Despite its strengths, FEA has some challenges:

- The method simplifies structures, which can cause inaccuracies.

- Computational limits, such as rounding errors, can affect results.

- User mistakes, like applying the wrong material data, can distort predictions.

Therefore, while FEA is powerful, it works best when combined with expert oversight and validation.

How Mettler Design Uses Finite Element Analysis (FEA)

At Mettler Design, we apply Finite Element Analysis (FEA) throughout the design process to optimize safety, reliability, and performance. Our team uses advanced software to simulate stress, strain, vibration, and thermal conditions on components before they reach production.

By integrating FEA into product development, we help clients:

- Reduce design cycles.

- Save costs on physical prototypes.

- Improve durability and compliance with safety standards.

If you are looking for reliable FEA services, visit the Mettler Design homepage to contact us today.