At Mettler Design, our engineers specialize in applying advanced simulations and mathematical modeling to improve the performance of modern electric vehicles. For this project, we focused on estimating the range of an electric scooter using the New European Drive Cycle (NEDC). By leveraging MATLAB-based models and factoring in duty cycles and cell temperature characteristics, we were able to accurately predict the scooter’s range while optimizing the battery size for cost and efficiency.

This project highlights how product design, prototyping, and manufacturing expertise can be combined with simulation to achieve lean, performance-driven solutions.

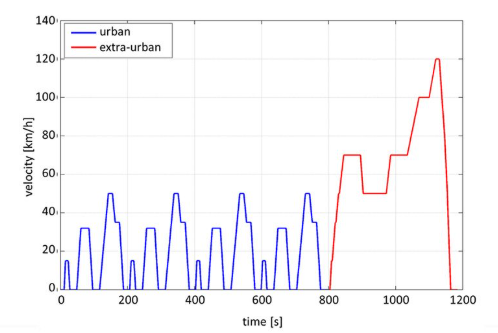

DRIVE CYCLE ANALYSIS

The NEDC consists of two sections: the Urban Cycle and the Extra-Urban Cycle. Since the scooter operates primarily in urban environments, we concentrated on the Urban Cycle to ensure accuracy and relevance. Consequently, our predictions reflected real-world city driving conditions, making them more practical for both the client and end-users.

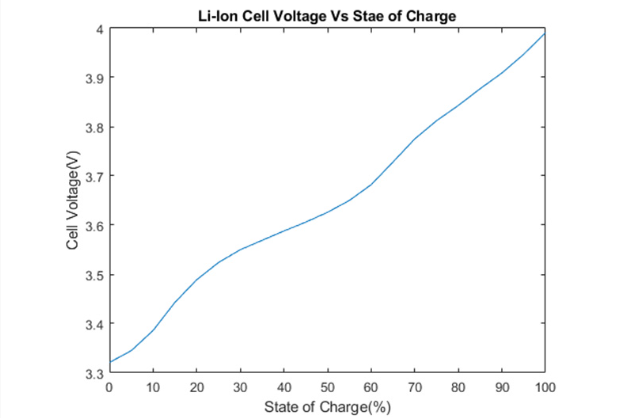

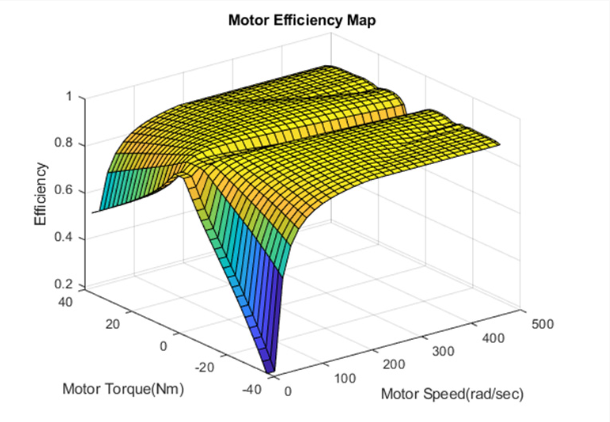

MATHEMATICAL MODEL FOUNDATIONS

To establish a reliable model, we developed plots of lithium-ion cell voltage at varying states of charge alongside motor efficiency graphs. These inputs formed the foundation of our range estimation models, enabling us to calculate with precision and validate every assumption with data-driven accuracy.

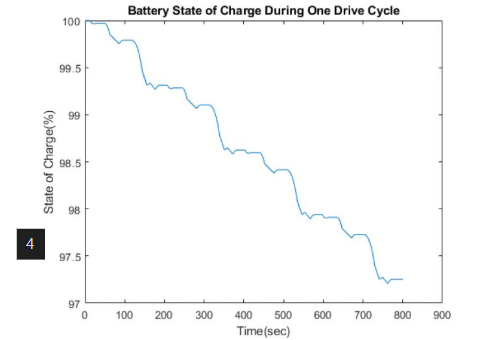

RANGE ESTIMATION AND BATTERY OPTIMIZATION

Using the model, we simulated battery utilization over a complete drive cycle, incorporating the effects of regenerative braking. This not only provided a clear understanding of energy flow but also identified opportunities for optimization.

Because the battery pack is one of the heaviest and most expensive components of an electric scooter, optimizing its size was critical. Our calculations aimed to reduce weight and costs while maintaining the required range. The outcome was a lean, optimized solution that improved the scooter’s commercial viability without compromising performance.